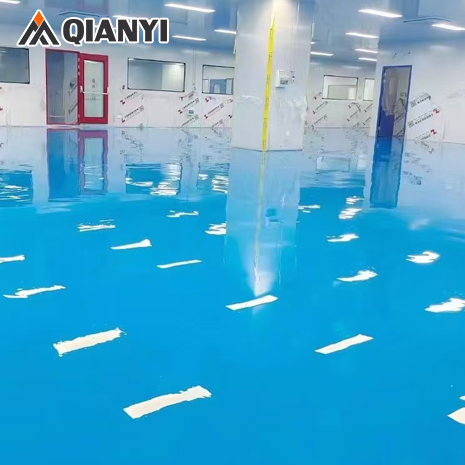

| Scope of application: | Micro bead flooring is suitable for anti slip factory workshops, underground garages, chemical plants, hardware, ramps, and sidewalks; Machinery, shipyards, automobile repair shops, canteens, and kitchens have a simple construction process for micro bead anti slip flooring, which only requires rolling and brushing once. After curing, it forms a highly anti slip and wear-resistant flooring |

| Coating characteristics: | Dustproof, moisture-proof, wear-resistant, pressure resistant, acid and alkali resistant |

| Easy to clean, seamless, mold and antibacterial, strong impact resistance |

| Strong adhesion, durable, and resistant to chemicals |

| Diverse colors |

| Fast construction and cost-effective |

| TECHNICAL INDEX | Drying time - surface drying: ≤ 4H |

| Drying time - practical: ≤ 24 hours |

| Pencil hardness: ≥ 6H |

| Impact resistance (500g steel ball): through g'cm |

| Wear resistance (750g/500r): ≤ 0.03g |

| Adhesion (grid method): Level 1 |

| Resistant to 10% saline solution: no significant change for 7 days |

| Resistant to 10% sulfuric acid: no significant change after 7 days |

| Resistant to 10% sodium oxide gas: no significant change after 7 days |

| Resistant to gasoline 120 # #: No significant change after 7 days |

| Construction procedures | construction method | Main materials - auxiliary materials | Reference amount |

| Plain ground | Do a good job in waterproofing treatment |

|

|

| undercoat | Scrape and apply epoxy primer once | DS-30# | About 0.1-0.15kg/m2 |

| screed | Add quartz sand to scrape and apply mortar | DS-400- Quartz sand | 0.5kg/m²

|

| Putty layer | Scrape the putty layer until it is flat and free of holes, as well as no batch marks or sanding marks | DS-400 | 0.15kg/m2 once |

| top coat | Apply the same colored topcoat evenly and scrape it off | DS-143 | 0.1kg/m2 once |

| wear layer | Apply micro bead topcoat evenly according to the dosage | DS-690 | 0.13kg/m2 once |

|

| Construction procedures | Coating thickness: generally 1mm-3mm. If it exceeds 2mm, it needs to be sandblasted |

| Personnel can only enter after 24 hours of construction completion, and heavy pressure can only be applied after 72 hours. (Based on 25 * C, the low-temperature opening time needs to be moderately extended) |