| Product composition | Prepared from epoxy resin, zinc powder, pigments, fillers, additives, solvents, amine curing agents, etc |

| Performance and Usage | Has cathodic protection function; Has excellent adhesion, impact resistance, and wear resistance; Has extensive oil and solvent resistance; Quick drying, long-lasting rust prevention; Used in conjunction with most high-performance anti rust paints and topcoats |

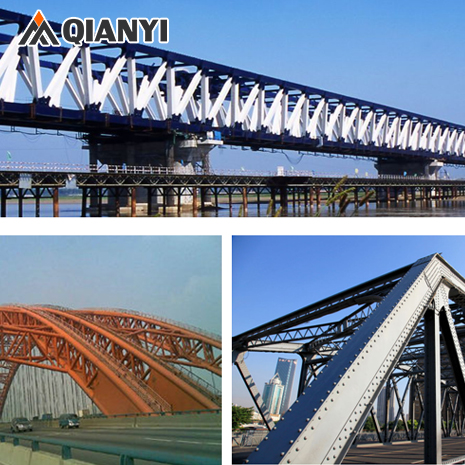

| Used as a rust proof primer for steel structures such as port machinery, heavy machinery, oil extraction and mining equipment, ship hulls and decks above the waterline, bridges, buried pipelines, and gas tank outer walls. It is the best primer for epoxy intermediate layer paint |

| colour | Metallic gray or matte |

| Physical parameters | Density - about 2.3g/ml |

| Applicable time -4 hours (25 ℃) |

| Dry film thickness -25 µ m |

| Wet film thickness -56 µ m |

| Theoretical dosage -7 ㎡/kg (dry film 25 µ m) |

| Salt water resistance - ≥ 168 hours without foaming, rusting, or peeling |

| Proportion - Component A: Component B=12:1 (weight ratio) |

| Drying time - surface drying ≤ 20 minutes; Practical work ≤ 16 hours (25 ℃) |

| Impact strength -50kg.cm |

| Adhesion force ---- ≤ 1 (grid method) |

Maturity period -10-15 minutes

|

| Interval time for recoating | One dish per day (20 ℃) |

| Supporting coatings | Epoxy, chlorinated rubber, polyurethane, acrylic and other topcoats |

| Substrate temperature | 3 ° C above dew point |

| instructions | 1. Steel with oxide scale, sandblasted to achieve Sa2.5 level according to Swedish standard SIS05 5900; Before rust removal, the surface oil stains must be completely removed, welding splashes must be removed, and the welds and sharp corners must be polished; This product is not recommended for manually removing embroidery on steel surfaces, except for small area repairs with good embroidery removal effect reaching St3 level |

| 2. Mix components A and B in proportion, add diluent appropriately to adjust the viscosity suitable for construction, and let it stand for 10-15 minutes before construction. After mixing the two components, they should be used up within 6 hours at 25 ℃ |

| coating method | Spray coating, roller coating, brush coating |

| thinner | Epoxy diluent |

| Storage period | Sealed storage in a cool and dry place, with a shelf life of 12 months. If it exceeds the shelf life and passes inspection, it can still be used |