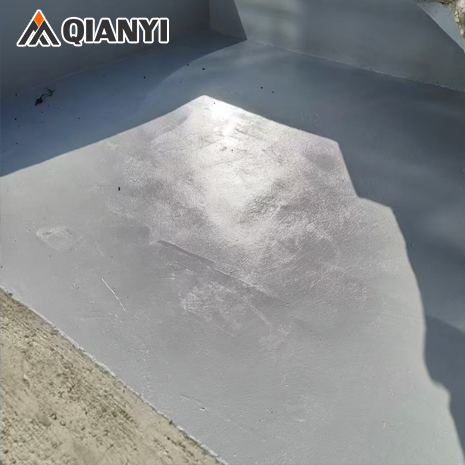

| Material Introduction | KED underground engineering protective material is composed of special hydrophobic polyurethane resin, siloxane, nano inorganic ceramics and other materials. It is a high-strength and high modulus anti-corrosion and anti-seepage material with high mechanical strength, high compressive strength, and can be constructed on wet substrates. It is an environmentally friendly material without VOC volatile substances |

| This technology is specifically designed for various underground engineering applications, such as non excavation repair of underground pipelines (anti-corrosion, reinforcement, anti-seepage); No need to excavate the road surface to replace new pipelines, reducing maintenance costs; Used for the reinforcement, repair, waterproofing, anti-seepage, and anti-corrosion of concrete buildings such as square ditches, pipe galleries, well chambers, water conveyance tunnels, and military caverns. The material can withstand high water pressure without seepage or bulging, and has excellent anti-corrosion performance, making it a new generation of concrete protection technology. Has more significant advantages than traditional photopolymerization materials |

| Traditional protective materials require the substrate to be dry, which cannot be achieved in underground pipeline construction. High pressure water flushing and dredging are required during underground pipeline construction, and even baking is difficult to meet the drying requirements, which is time-consuming and labor-intensive. KED technology can be used for construction on damp surfaces, and when combined firmly, it solves a major problem. |

| This technology can be applied to underground utility tunnels, underground trenches, and various aging well chambers. There are already a large number of mature applications available now. According to different application scenarios, there are corresponding specialized materials with different performance. |

| Main performance parameters of the product | project | parameter

|

| Solid content,% | 100 |

| Gel time, S | 8-20

|

| Bending modulus, MPa | 200-5000 |

| Bending strength, MPa | 60-120

|

| Hardness, Shore D | 75-81 |

| Compressive strength, MPa | 103 |

| Dielectric strength, KV/mm | 28 |

| Tensile strength, MPa | 40-100 |

| Corrosion Resistance | 50% H, no bulging or sticking in SO |

| No bulging or sticking in 40% NaOH |

| No bulging or sticking in saturated saltwater |

| Surface resistivity, Q | 3.4x10 |

| Fracture elongation,% | 5-10

|

| Product advantages | Special spraying equipment is used for spraying construction, which automatically measures and mixes to avoid quality problems caused by manual measurement and mixing, making it more reliable and ensuring quality |

| Fast curing speed, can be put into use within 2 hours after spraying construction |

| No VOC emissions, environmentally friendly and non-toxic, meeting the needs of the latest environmental situation |

| Can be continuously sprayed to any thickness, without the need for long intervals between each coat like traditional coatings, with high construction efficiency |

| Has a higher ability to withstand water pressure, will not bulge or fall off |

| Corrosion resistance, aging resistance, long service life, with a service life of over 50 years underground after coating |

| For ultra large diameter pipe galleries and pipelines, KED underground engineering protective materials have more obvious convenience than UV curing solutions |

| application area | Used for anti-corrosion reinforcement and anti-seepage of square ditches, pipe galleries, well chambers, sedimentation tanks, and box culverts |

| Waterproof and anti-seepage measures for water diversion and water conveyance tunnels used in water conservancy systems |

| Waterproof and anti-seepage measures for concrete used in military caverns, oil emergency reserve caverns, and other facilities |

| Repair and anti-seepage of underground concrete pipelines used in municipal engineering |