Detailed introduction

| Material Introduction | KED solvent-free heavy-duty anti-corrosion coating is a modified high-performance polymer anti-corrosion coating, designed with a special formula and integrating multiple cutting-edge technologies. This product has the characteristics of low water absorption, strong impermeability, excellent anti-corrosion performance, and salt spray resistance. It is sprayed and formed on site using specialized equipment and can meet most anti-corrosion environments. It is suitable for metal anti-corrosion applications immersed in seawater, sewage, acid alkali salt liquids, and can also be used in corrosive gas environments | |||

| Product advantages: | ||||

| Safety and Environmental Protection | Solvent free, high solid content, safe construction, environmentally friendly | |||

| Excellent anti-corrosion performance | The molded coating is dense, seamless, has good hydrolysis resistance, high electrical strength, and good insulation, which can effectively suppress the electrochemical corrosion of metals and withstand the erosion of highly corrosive media | |||

| Long anti-corrosion life | Not easily hydrolyzed, stable performance, fully ensuring that the coating is not easily damaged and guaranteeing anti-corrosion performance | |||

| High construction efficiency | Room temperature curing without heating | |||

| Main performance indicators of the product | ||||

| project | parameter | project | parameter | |

| Solid content,% | 98 | Hardness, Shore D | 65 | |

| Table drying time, s | 10-120 | Tensile strength, MPa | 20-35 | |

| Bond strength with carbon steel, MPa; | 13.6 | Fracture elongation,% | 20 | |

| Electrical strength, kV/mm | 28 | Wear resistance, mg (CS-10 rubber wheel 750g/500r) | 15 | |

| Water absorption rate, , %,23°C | 0.8 | Water absorption rate,%, 50C | 1.3 | |

| solvent resistance | corrosive medium | Concentration (%) | time | state |

| sulfuric acid | 5-40 | half a year | unchanged | |

| sulfuric acid | 50 | half a year | unchanged | |

| sulfuric acid | 5-10 | half a year | unchanged | |

| sodium hydroxide | 40 | half a year | unchanged | |

| sodium hydroxide | 40 | half a year | unchanged | |

| Formaldehyde (formalin) | 10-25 | half a year | unchanged | |

| hydrochloric acid | 10-25 | half a year | unchanged | |

| acetic acid | 5-40 | half a year | unchanged | |

| phosphoric acid | 10 | half a year | unchanged | |

| Aminofluoric acid | 40 | 100 days | unchanged | |

| sodium chloride | 36(saturated) | half a year | unchanged | |

| phenol | 8 | half a year | unchanged | |

| ammonia | 25 | a year | unchanged | |

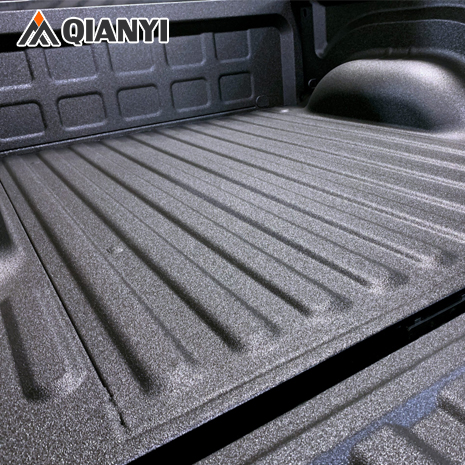

| coating method | Spray coating construction | |||

| Recommended thickness is 2-3mm; theoretical coating amount is 1.2kg/(m2. mm); Actual consumption is subject to on-site working conditions | ||||

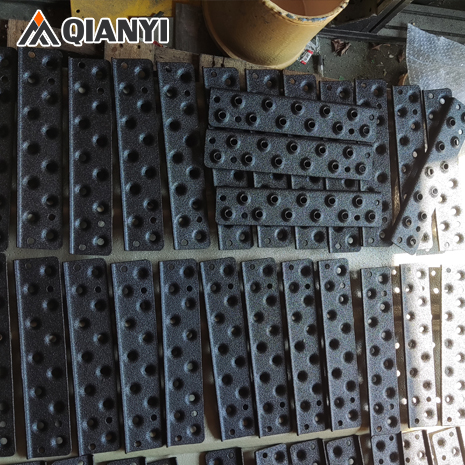

| application area | Corrosion prevention of blast furnace gas pipelines in steel mills | |||

| Anti corrosion of sewage and seawater pipelines | ||||

| Special steel structure with heavy anti-corrosion | ||||